Food industry

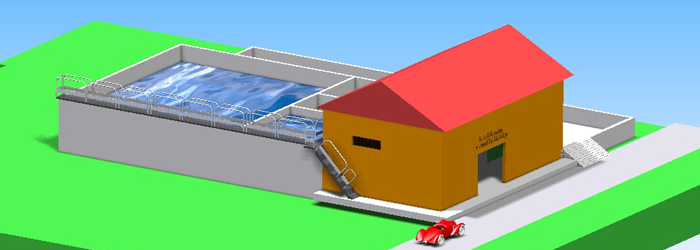

Fornetti SRL, Romania

Status: working

Bakery factory

Quantity of wastewater 250 m³/d

Outlet: watering of a poplar forest

Year of construction 2009

www.fornetti.ro

google maps

Bakery factory

Quantity of wastewater 250 m³/d

Outlet: watering of a poplar forest

Year of construction 2009

www.fornetti.ro

google maps

- Particularly difficult to clean bakery waste water

- The bakery had no connection to a sewer system. The waste water was transported by truck to the nearest treatment plant 25 km away.

- Because of the high cost of this solution and the increase in the amount of waste water due to the expansion of production, the construction of an own sewage treatment plant was decided.

- The requirements of the company's management were: low operating costs for wastewater treatment, lower staff costs, protect the environment, strict compliance with the Romanian norms NTPA 001/2005, trouble-free operation, automatic adaptation to different amounts of waste water

- To meet the requirements, a waste water treatment plant was built in a compact design with sieving, homogenization, flocculation, flotation, SBR-biology and sludge dewatering. Automatic operation, very low maintenance and service costs.

- The results are in line with statutory requirements and undercut the guidelines.

- The purified waste water is directed into a specially-made lake of 1 ha. The lake serves to irrigate a poplar forest.

Hajduvid Vágóhid KFT, Hungary

Status: working

Poultry slaughterhouse

Quantity of wastewater 900 m³/d

Outlet: municipal sewer

Year of construction 2009

Poultry slaughterhouse

Quantity of wastewater 900 m³/d

Outlet: municipal sewer

Year of construction 2009

- Installation and adjustment in an old disused industrial building

- 900 m³ / d conducted in the municipal sewage system

- Strong fluctuations in the flow (20 to 60 m³ / h) and the pollution load (2000-8000 mg / l COD)

Tordai Impex SRL, Romania

Status: working

Slaughterhouse

Quantity of wastewater 150 m³/d

Outlet: municipal sewer

Year of construction 2007

Slaughterhouse

Quantity of wastewater 150 m³/d

Outlet: municipal sewer

Year of construction 2007

- Beef and pork slaughterhouse in residential area

- Due to lack of space very compact design with buffer and biology basin below the machine room

- Installation and set up within a week

- Use of air biofilter for odor reduction

Specific slaughterhouse in East Hungary

Status: working

Slaughterhouse for fish

Quantity of wastewater 150 m³/d

Year of construction 2007

Slaughterhouse for fish

Quantity of wastewater 150 m³/d

Year of construction 2007

- Very strict rules, as the slaughterhouse is situated in the middle of a conservation area

- Special design of the mechanical pre-screening for fish scales

- Use of generously dimensioned air biofilter for odor reduction

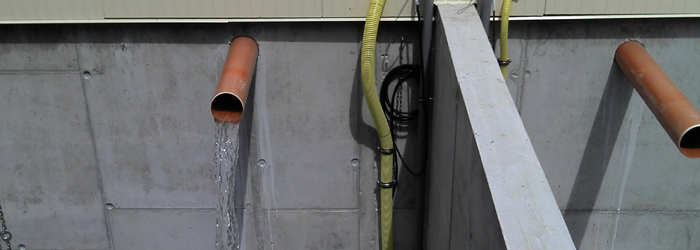

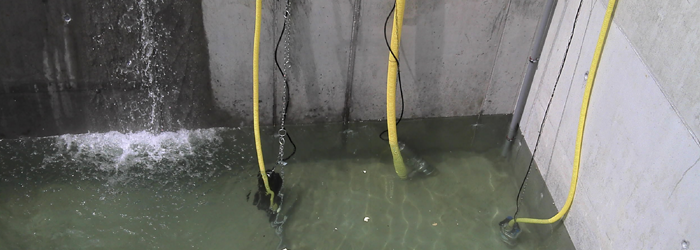

Kecel Fejes +Tsa KFT, Hungary

Status: working

Slaughterhouse

Quantity of wastewater 150 m³/d

Year of construction 2007

Slaughterhouse

Quantity of wastewater 150 m³/d

Year of construction 2007

- Sieve, flocculation, flotation, small biological treatment

- Poplar forest irrigation

- Old reservoir reused as biology basin

- New machine shop made of sandwich panel elements

Dosa Srl, Romania

Status: working

Slaughterhouse

Quantity of wastewater 60 m³/d

Year of construction 2009

google maps

Slaughterhouse

Quantity of wastewater 60 m³/d

Year of construction 2009

google maps

- Purified waste water is discharged into a particularly sensitive mountain stream

- Technology: buffering, screening, flocculation, flotation, semi-SBR, biology, sludge dewatering

- Only 2 months from planning to commissioning

- Supply, construction and installation of plant parts within a week

- Reaching the legal limits within a week after start.

- Adaptation of architecture in the local mountains

Dairy plant in East Hungary

Status: done

Milk products

Quantity of wastewater 60 m³/d

Outlet: municipal sewer

Milk products

Quantity of wastewater 60 m³/d

Outlet: municipal sewer

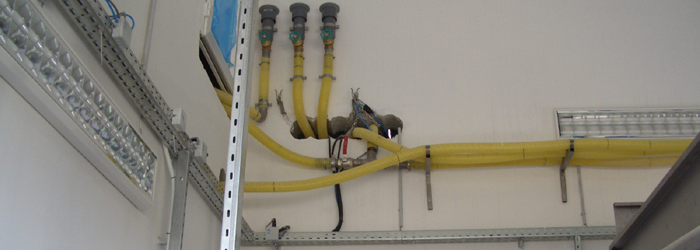

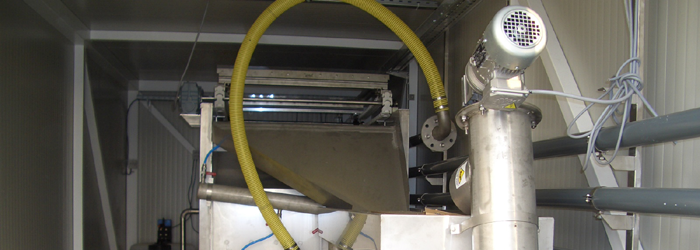

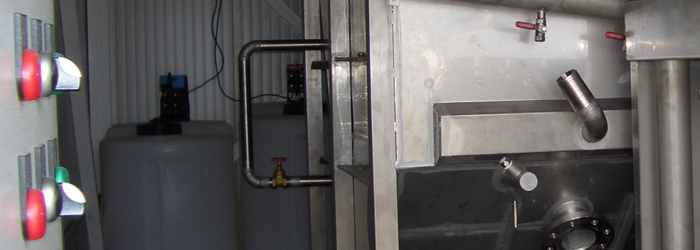

- Compact design, integrated in a specially constructed insulated container with standard masses

- Ready to use

- Buffering, screening, flocculation with dosing of chemicals and pH control, flotation, sludge dewatering, fully automatic operation